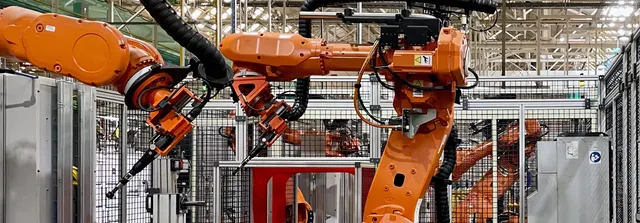

Manufacturing

Manufacturing demands precision and we deliver the technology to optimize, automate, and scale every part of your operations.

Trusted by

Key Challenges in manufacturing

Changing consumer trends

Customer are changing their behavior faster than ever, putting pressure on companies to remain flexible and adjust to new trends.

Omnichannel integration

Customers expect a seamless experience across multiple channels, for a convenient and always available shopping options.

Keeping up with technology

Customers expect businesses to integrate new technologies such as AI chatbots and assistants, AR features, automated services, and other modern functionalities that require heavy investment.

How We Support manufacturing

Gauss Box: AI-powered manufacturing backbone

Manufacturing industry demands precision, efficiency, and no downtime. Inefficiencies, wrong timing, and uninformed decisions can lead to costly downtime and lost productivity.

With Gauss Box, you don't just keep up, you stay ahead. Seamlessly connect your entire manufacturing ecosystem - from the factory floor to the supply chain - giving you full control, real-time insights, and automation that works for you.

How Gauss Box transforms your manufacturing processes:

Supply chain overview and management

Replace static spreadsheets and file folders with agile tables that can track inventory, input materials, waste, and other aspects of the supply chain important for seamless production.

Analytics and real-time data insights

Easily track relevant KPIs and important data using editable dashboards and widgets, while creating comprehensive reports in a few clicks.

Easy production planning

Take advantage of automatization and functionalities that help you plan out production and adjust it as needed when unexpected issues occur - making you more agile and avoid downtime.

Documentation management

Easily create documents automatically or by hand, manage and archive them digitally, becoming more efficient and sustainable.

Security and compliance

Ensure compliance and safeguard your data with robust security features and built-in compliance features.

Custom manufacturing solutions for your needs

Every manufacturing operation has its own complexities—specific workflows, production lines, and supply chain requirements that demand tailored solutions.

We build custom technology that is designed to fit your exact needs, whether by enhancing existing systems or developing entirely new solutions.

How custom solutions can transform your manufacturing operation:

IoT-powered smart factories

Monitor and manage every stage of manufacturing with smart devices that collect real-time data, automate processes, reduces errors, and supports timely decision making.

Full system digitalization and transformation

Transform manufacturing with digitalization, from production tracking to inventory management, boosting productivity.

Predictive maintenance

Prevent downtime and avoid costly repairs with AI predictive maintenance that identifies failures before they happen.

Long-term cost efficiency

Reduce waste, optimize resources, and improve production speed with a solution that scales with your business growth.

Software designed for your processes

Rely on custom-built software that is tailored to your specific needs, seamlessly integrating with your workflows.

Exceeding toughest manufacturing standards

With regulations, audits, and security risks, manufacturers cannot afford gaps in compliance.

That’s why we build solutions according to the highest standards - ensuring that your operations are secure, compliant, and audit-ready.

Industry-leading compliance and security

ISO 9001, 27001, and 30301:2019 certified

We ensure that our organization and products meet international standards for quality management, information security, and effective management systems.

Advanced protective technology

We implement advanced protective technologies that ensure the ongoing safety and integrity of your data, while safeguarding it from threats and hardware failures.

Live risk and compliance monitoring

Stay ahead of safety, regulatory, and security challenges with real-time monitoring and instant alerts. Our solutions provide continuous oversight, ensuring you stay informed and in control at all times.

AI for manufacturing

Manufacturing operations are complex, with unique workflows, production lines, and supply chain demands - requiring intelligent, adaptable solutions.

Our AI-powered technology is designed to handle these complexities, optimizing processes while seamlessly adapting to your specific needs.

How AI transforms manufacturing:

Keep your production running smoothly

Rely on AI-driven monitoring to detect early signs of machine wear and potential failures before they escalate. Schedule maintenance proactively, minimize unexpected downtime, and keep operations running at peak efficiency.

Improve product quality and catch defects instantly

Implement computer vision systems to inspect every product in real time. Reduce defects, minimize waste, prevent costly recalls while consistently delivering high-quality products.

Smoother operations with smarter supply chains

AI forecasting enables precise demand predictions, real-time inventory tracking, and optimized logistics. Get the right materials at the right time, eliminating overstock, shortages, and unexpected disruptions that slow production.

AI powered tool that work for you, not the other way around

Every factory is different. That's why we don't believe in one-size-fits-all AI. We customize AI solutions for your specific machines, workflows, and goals.

Why Gauss solutions are ideal for your production:

• Works with your existing systems - no need for a total overhaul

• Easy to implement and scale - start small and expand as needed

• Designed for real-world results, not just fancy tech demos

AI is already changing manufacturing and the companies that use it well will be the ones that stay ahead.

Manufacturing Success Stories

+150 industry leaders have trusted Gauss

With more than 150 employees, we were tired of using spreadsheets and email to manage our internal projects. Luckily, we tried Gauss Box and improved our process significantly!

Mislav Mihalj

Sales director, Hemco

Your partner for manufacturing

Years of creating digital solutions

Manufacturing industries experience

Ready-made digital platforms for manufacturing

.webp)

Got a project in mind? Let's talk business!

Schedule a meetingFrequently asked questions

At Gauss, we go beyond one-size-fits-all solutions. Our AI-powered and custom-built technologies are designed to fully adapt to your unique manufacturing processes, ensuring seamless integration, optimized workflows, and real results. With a decade of expertise, we deliver solutions that don’t just keep up with industry demands but push your operations forward

Gauss solutions are built for flexibility. Whether you need to enhance your existing ERP, connect disjointed systems, or introduce AI-driven optimizations, we seamlessly integrate with your current technology stack - maximizing efficiency without disrupting operations

Our AI-powered tools predict potential machine failures before they happen, enabling predictive maintenance that minimizes costly downtime. We also optimize production scheduling, automate workflows, and enhance real-time decision-making

Security is at the core of everything we build. Our solutions follow the highest industry standards for data protection, including encryption, access controls, and compliance with regulatory requirements. You stay in control of your data while we ensure it remains safe and uncompromised.

Implementation time depends on the complexity of your needs. With Gauss Box, we offer rapid deployment for businesses looking for immediate digital transformation, while fully custom solutions may take months to develop and implement.