Key takeaways

- AI is used to transform traditional logistics operations through intelligent algorithms that forecast demand, optimize routes, and enhance warehouse efficiency, reducing costs by up to 50% while improving inventory levels by 35%.

- AI can be used for predictive maintenance, automated document processing, and dynamic pricing strategies, saving 8-12% in maintenance costs and increasing revenue by 5-10% through optimized pricing models.

- AI implementation in supply chain operations addresses traditional limitations like poor visibility (reported by 44% of executives) and traffic congestion ($74.5 billion annual cost), while enabling enhanced sustainability through reduced fuel consumption and emissions.

- Companies that successfully implement AI-powered logistics solutions gain competitive advantages through improved customer experiences, with 97% of manufacturing CEOs planning to improve logistics operations with AI technology by 2026.

AI's Role in Modern Logistics

What Defines AI Technology in Logistics

AI in logistics transforms how companies manage their operations through intelligent algorithms that forecast demand, plan shipments, and optimize warehousing.

AI algorithms help logistics professionals predict transit times and find alternate routes during disruptions.

AI models trained on past orders improve performance without constant human input.

Early adopters of AI-powered supply chain management software have seen impressive results – 15% lower logistics costs than competitors and inventory levels improved by 35%.

The technology extends to customer service through AI-powered chatbots that handle inquiries and analyze complaints.

Artificial intelligence in logistics excels at processing massive data sets to create reliable operational forecasts.

How AI Addresses Traditional Logistics Limitations

Traditional logistics struggles with unexpected breakdowns, poor route planning, and limited supply chain visibility.

Manual processes cost warehouses approximately 3,000 hours annually.

AI can help reduce operational costs by up to 50% while increasing warehouse safety by 90%.

AI-powered predictive analytics spots potential delays before they happen using real-time data.

The technology optimizes delivery routes, cutting transit times and fuel use with efficiency gains of up to 30%.

For logistics operations facing visibility challenges (reported by 44% of supply chain executives), AI provides effective solutions for managing disruptions.

Traffic congestion costs the logistics industry $74.5 billion annually, which AI in logistics operations helps minimize through real-time analysis.

AI's predictive capabilities ensure proactive planning for unexpected events, significantly reducing downtime during peak demand periods.

The Evolution from Manual to Intelligent Operations

The logistics industry has transformed from manual processes to smart systems, with 38% of logistics companies actively using AI technologies.

Before adopting AI, about two-thirds of warehouse activities were manually performed.

Experts predict AI will boost logistics productivity by more than 40% by 2035.

AI-powered robots now handle functions traditionally performed by humans.

Where conventional forecasting relied on internal historical data, modern tools analyze third-party information about weather, events, and customer patterns.

Traditional maintenance schedules are giving way to predictive systems that identify problems beforehand through sensor data analysis.

Manual document processing is being automated through technologies like Optical Character Recognition and Natural Language Processing.

This transformation continues accelerating – a 2024 survey found 97% of manufacturing CEOs plan to implement AI within the next two years.

Key Benefits of AI-Powered Logistics Operations

Operational Efficiency Improvements

Operational efficiency improves dramatically with AI-powered systems.

These applications help demand forecasters predict delivery delays and help warehouse managers optimize container space.

AI suggests optimal warehouse layouts and worker routes to speed fulfillment.

AI-powered transportation management predicts shipment ETAs during planning and while products are in transit.

AI tools analyze shipping times, allowing logistics managers to identify and avoid risky lanes.

Warehouse operations become more efficient through AI-driven automation that increases order fulfillment rates through better inventory placement based on historical demand data.

Safety improves as AI-powered dashboard systems detect risks both inside vehicles (like distracted drivers) and outside (such as imminent collisions or road condition changes), ensuring more reliable delivery times.

Cost Reduction Opportunities

AI-based predictive analytics optimizes inventory levels, preventing stockouts while reducing surplus volume.

Successfully implementing AI-enabled supply chain management reduces logistics costs by 15% compared to competitors.

AI helps identify products with high return rates, uncovering potential defects or market mismatches.

AI-powered maintenance systems predict equipment failures, allowing proactive maintenance scheduling.

With shipping and aviation projected to account for nearly 40% of global CO2 emissions by 2050, reduce operational costs through more efficient routing and load optimization.

The World Economic Forum estimated 15% of trucking miles in 2021 were driven empty – a wasteful practice that inventory levels optimization addresses.

Companies using AI for predictive maintenance save 8-12% over preventive maintenance and up to 40% over reactive maintenance according to U.S. Department of Energy figures.

Enhanced Supply Chain Visibility

AI enables organizations to track goods through every supply chain stage, ensuring suppliers follow fair labor laws and sustainable practices.

AI systems detect anomalies in processes, deliveries, and product quality before they escalate.

Machine learning algorithms analyze large datasets from multiple sources to provide comprehensive visibility across the supply chain network.

For perishable items, AI enhances traceability by monitoring temperature and other critical conditions during transport.

Predictive analytics forecasts potential bottlenecks, allowing proactive management of supply chains.

The identification of patterns across supplier networks creates additional optimization opportunities.

Environmental Sustainability Gains

Transportation networks benefit from AI optimization that accounts for traffic, weather, and delivery locations, reducing carbon emissions and fuel consumption.

Route planning algorithms reduce unnecessary mileage, directly lowering greenhouse gas emissions.

AI identifies the most fuel-efficient transportation routes by analyzing traffic and weather patterns.

Even warehousing becomes more sustainable with automated systems that reduce energy consumption through optimized space utilization.

Transportation and logistics companies implementing these solutions meet sustainability expectations while reducing operational costs.

Customer Experience Enhancement

Customer experience improves through AI-powered tools that automate shipping label creation and reduce errors.

AI chatbots respond to logistics queries instantly, while real-time tracking enhances the overall experience.

AI helps identify at-risk shipments so managers can take proactive action to maintain delivery promises.

For perishable goods, autonomous tracking of temperature and conditions ensures products arrive in perfect condition.

Market trends show customers increasingly value visibility and reliability from logistics service providers, creating competitive advantages for companies leveraging AI technologies.

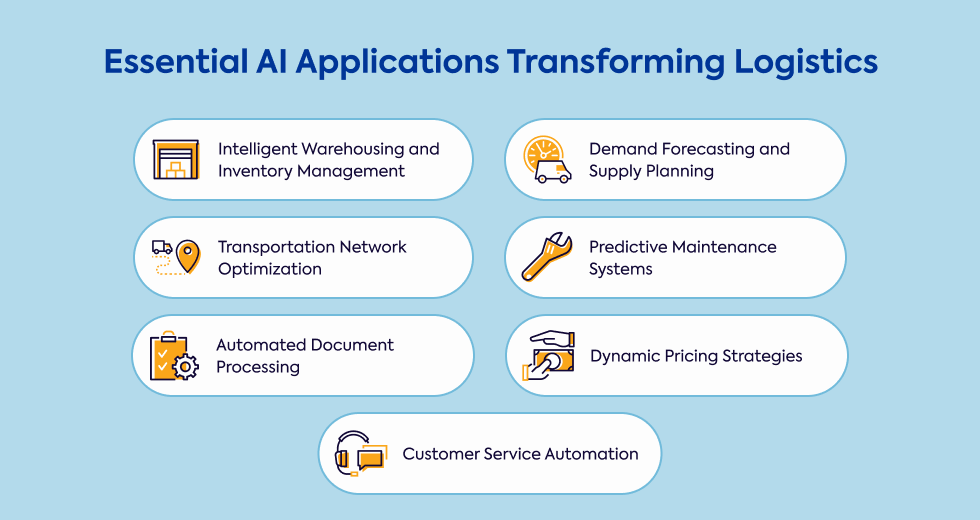

Essential AI Applications Transforming Logistics

Intelligent Warehousing and Inventory Management

Warehouse operations have been revolutionized by AI systems.

AI-powered management tools identify orders with fulfillment times that exceed targets, allowing prioritization of time-sensitive shipments.

Companies like Amazon have deployed over 200,000 robots for warehouse tasks, working alongside human employees to increase throughput while reducing errors.

Inventory management benefits from AI-based predictive analytics that optimize stock levels using historical data and real-time demand signals.

Industry experts project that by 2026, over 60% of businesses will adopt AI-powered warehouse solutions.

Companies like GreyOrange combine robotics with machine learning algorithms to create systems that pick, sort, and pack goods with greater accuracy and speed than humans alone.

These systems continuously learn and adapt, reorganizing warehouse space based on predicted demand patterns.

Demand Forecasting and Supply Planning

Demand forecasting has evolved through AI-powered methods that significantly reduce error rates compared to traditional approaches.

Machine learning solutions support planning through advanced scenario analysis and numerical analytics at scale.

Artificial intelligence helps businesses analyze demand in real-time, allowing dynamic supply planning parameter updates.

The systems incorporate variables like weather patterns, regional events, and customer trends to improve forecasting accuracy.

As these systems process more data, their precision continuously improves.

Improved accuracy helps manufacturers optimize vehicle dispatches to warehouses, reducing transportation costs while ensuring product availability.

Historical sales data provides the foundation, but modern AI looks beyond past transactions to current market conditions and emerging trends that affect demand.

Transportation Network Optimization

Route optimization stands at the heart of modern logistics efficiency.

AI analyzes factors like traffic, sea currents, and weather to fine-tune routes and map alternatives.

Sophisticated shortest-path algorithms identify the most efficient paths for logistics trucks, addressing the $74.5 billion lost annually to traffic congestion.

Supply chain efficiency improves when AI supports "last-mile planning" by analyzing delivery locations and vehicle capacities.

Fleet management applications determine the optimal carrier mix and automatically assign loads to drivers.

Technologies like platooning support driver safety while reducing emissions and fuel usage.

Logistics processes have become increasingly complex, but AI helps manage this complexity through continuous learning capabilities that improve routes as systems gather more data about actual conditions.

Predictive Maintenance Systems

Predictive maintenance revolutionizes equipment management through AI that analyzes real-time sensor data to predict potential failures.

Machine learning-powered analytics identify patterns indicating developing problems.

According to the U.S. Department of Energy, predictive maintenance reduces costs by 8-12% compared to preventive maintenance and up to 40% over reactive approaches.

The significant benefits extend beyond direct savings.

AI helps extend equipment life by identifying maintenance needs early.

Companies like DINGO have enhanced their capabilities through machine learning, achieving measurable business outcomes within 2-3 months of implementation.

Sensor data provides insights into equipment usage patterns, potential design improvements, and operator training opportunities, transforming overall operational efficiency.

Automated Document Processing

Document processing has been streamlined through AI technologies. GenAI-based capabilities automatically extract text from digital files, even from illegible documents.

This technology creates digital receipts from bills of lading and digitizes paper invoices for payables systems.

AI uses Optical Character Recognition and Natural Language Processing to extract crucial information from documents, resulting in faster data entry, reduced errors, and significant time savings.

The systems efficiently manage, organize, and retrieve documents, streamlining workflows throughout the organization.

For international shipments, automated systems handle multiple languages and document formats, ensuring smooth cross-border operations with fewer errors and better regulatory compliance.

Dynamic Pricing Strategies

The AI system approach to pricing has transformed rate-setting practices.

Dynamic models replace static pricing by constantly adjusting rates based on market demand analysis.

AI algorithms analyze customer data in real-time, enabling faster responses to demand fluctuations through automatic price adjustments.

Among the benefits of AI, dynamic pricing helps businesses adapt to market changes more efficiently than fixed models.

Used in logistics from parcel shipping to freight transportation, these systems account for variables like fuel costs, capacity, and competitor pricing, optimizing revenue without market share loss.

Companies implementing dynamic pricing typically see revenue increases of 5-10% while maintaining competitiveness, representing one of the most valuable use cases for artificial intelligence in transportation.

Customer Service Automation

AI applications have transformed customer interactions.

Businesses deploy GenAI-based chatbots for common logistics queries, providing immediate answers without human intervention.

Natural language interfaces allow conversation-based information access rather than complex database searches.

AI systems track customer interactions and success rates to improve service efficiency.

Major companies have embraced this approach – Western Digital uses Logibot to provide 24/7 logistics information to partners.

These AI-powered systems handle tasks from delivery requests to shipment tracking and FAQs.

Analytics capabilities provide additional value, helping businesses understand customers better while creating continuous improvement feedback loops.

The technology transforms logistics by automating routine interactions while gathering valuable customer intelligence.

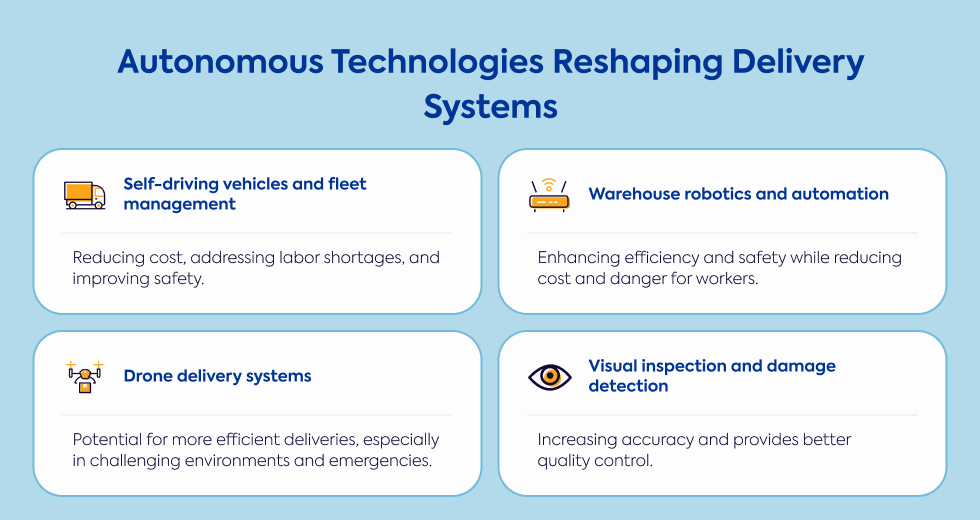

Autonomous Technologies Reshaping Delivery Systems

Self-Driving Vehicles and Fleet Management

Autonomous vehicles represent a major logistics advancement.

Companies like Tesla, Google, and Mercedes Benz are investing heavily, with BCG estimating 10% of light trucks will drive autonomously by 2030.

Nuro develops AI-powered autonomous vehicles for unmanned deliveries, reducing errors and congestion.

The Tesla Semi offers impressive capabilities with a 500-mile range and advanced autopilot features pointing toward autonomous freight transport.

Pilot programs promise significant cost reductions and improved delivery times through continuous vehicle utilization.

Logistics AI extends to safety systems that detect risks inside vehicles and external dangers.

Self-driving technologies have the potential to address driver shortages while improving safety and efficiency.

These systems analyze traffic, road conditions, and delivery constraints to determine optimal routes that human drivers might miss.

Warehouse Robotics and Automation

Artificial intelligence has transformed warehouse operations across the logistics industry.

Amazon leads with 200,000+ robots handling picking, sorting, and transporting alongside humans.

Industry projections suggest over 60% of businesses will adopt AI-powered warehouse solutions by 2026.

Logistics companies use AI to enhance efficiency and safety.

AI-powered robots store and pick products with greater speed and accuracy, reducing errors and injuries.

Companies like GreyOrange combine robotics with machine learning for remarkable sorting and packing speed.

Since AI adoption began accelerating, warehouses have become safer, more efficient, and more responsive to changing demand patterns.

Robots adapt to dynamic environments, optimizing workflows and ensuring coordination with other automated systems, providing competitive advantages through faster fulfillment and lower costs.

Drone Delivery Systems

Leveraging AI for last-mile delivery opens new possibilities.

Delivery drones transport products where ground transfer isn't practical, particularly valuable in challenging environments or emergencies.

Healthcare logistics demonstrates this potential – drones deliver pharmaceutical products with short shelf lives, reducing waste and eliminating costly remote storage facilities.

The "Deliver Future" project by DHL, GIZ, and Wingcopter successfully tested medicine deliveries to isolated areas in eastern Africa.

AI capabilities enable navigation, obstacle avoidance, and landing procedures that would challenge human pilots.

Amazon and other retailers are testing systems that rely on AI for optimization and safety in complex environments.

As regulations evolve, drone deliveries will likely become common for high-value, time-sensitive shipments.

Visual Inspection and Damage Detection

Software solutions for visual inspection have transformed quality control.

Computer vision enables damage identification and quality control throughout warehouse operations.

Google Cloud Visual Inspection AI automates quality control through advanced AI and computer vision, supporting ultra-high resolution images for precise defect detection.

Customers report up to 10x accuracy improvements over traditional machine learning while requiring fewer labeled training images.

Beyond anomaly detection, AI visual systems identify, classify, and locate multiple defects in single images, enabling automated follow-up tasks.

Industry expertise plays a crucial role in effective implementation.

Within the company, visual inspection systems analyze data to identify process improvements or training needs that reduce error frequency, creating not just better detection but fewer problems overall.

Overcoming Implementation Challenges

Investment and ROI Considerations

Implementing AI in logistics operations requires significant investment.

Systems can be expensive to purchase, integrate, and maintain, with substantial hardware, software, and infrastructure costs.

In 2023, companies spent an average of 267 euros per employee on software.

Despite high initial costs, implementing AI in logistics can reduce operating costs by up to 50%, helping companies achieve positive ROI faster than expected.

To maximize returns, businesses should prioritize high-value AI development cases requiring minimal effort while providing clear benefits.

Logistics requires realistic financial planning accounting for both immediate expenses and long-term benefits.

Focus on projects addressing specific operational pain points rather than implementing technology for its own sake for faster returns and stronger organizational support.

Legacy System Integration Strategies

Integrating sophisticated AI solutions with legacy IT systems presents major challenges.

The process is complex and often requires specialized systems integrators.

Many logistics companies underestimate the change required to existing infrastructure, leading to project delays.

Organizations typically experience downtime when integrating new AI capabilities into legacy applications.

Cloud-based solutions often provide smoother implementation, with improvements delivered more seamlessly than on-premises systems.

Integration challenges can be addressed through detailed scoping that clearly defines problems and solutions.

Different AI solutions might require different approaches, so flexibility remains important throughout implementation.

Data Quality and Accessibility Requirements

AI solutions depend entirely on underlying data quality and accessibility.

Successful implementation requires preparing information to ensure compatibility across systems.

Data must be collected from various sources to create a complete operational picture.

AI in logistics requires clean, structured data to deliver accurate insights.

APIs and interfaces must be established to ensure proper information flow between systems.

Data preparation represents a critical phase before model creation and testing can begin effectively.

Different AI solutions have different data requirements, so understanding these needs helps companies prepare effectively.

Improvement comes through careful attention to data quality, with regular audits and maintenance ensuring continued accuracy.

Talent Acquisition and Training Needs

The logistics landscape faces significant challenges finding qualified AI personnel.

There's a shortage of staff skilled in machine learning, data science, and AI development for logistics applications.

One study projected 1.5 million managers and analysts would lack big data analysis know-how for effective decisions.

Existing employees often need extensive retraining to work alongside AI systems.

Training must continue post-implementation for users to effectively utilize these tools.

Companies should schedule downtime for familiarizing employees with new AI capabilities, recognizing temporary productivity decreases during learning periods.

Industry expertise proves particularly valuable during implementation, as specialists understanding both technology and logistics operations can bridge the gap between technical capabilities and business needs.

Privacy and Security Concerns

Logistics companies face security challenges with new technologies.

Legacy on-premises applications require constant security patches, while cloud-based AI-powered logistics applications receive automated updates that improve security and privacy protection.

Historical cybersecurity breaches have damaged confidence in technology solutions.

In April 2021, C&C Group subsidiary Bulmers experienced a security incident forcing manual order fulfillment while restoring online capabilities.

Businesses must evaluate if AI in logistics operations is appropriate for certain processes or if other automation would present fewer security risks.

When handling customer information, privacy concerns must be thoroughly addressed to maintain regulatory compliance.

Industry expertise in both security and AI helps companies navigate these challenges effectively.

Ready to Transform Your Logistics Operations with AI?

While 97% of manufacturing CEOs plan to implement AI in their logistics operations by 2026, many companies struggle with the complexities of integration, data quality challenges, and finding qualified personnel.

At Gauss, we understand the logistics industry's unique challenges—from costly traffic congestion to poor supply chain visibility and inefficient warehouse operations.

Our custom AI solutions are designed to help you:

- Significantly reduce operational costs

- Optimize inventory management

- Enhance warehouse safety and efficiency

- Implement smarter maintenance systems

- Streamline transportation networks and routing

Don't navigate the AI implementation journey alone.

Our team of experts specializes in creating seamless integrations between cutting-edge AI technologies and your existing systems, addressing the exact pain points highlighted in this article.

Contact Gauss today to discuss how our custom AI solutions can transform your logistics operations and give you a competitive edge in an increasingly complex supply chain environment.